Aerospace 3D Printing Materials Market Key Takeaways

-

With 53% share, North America dominated the 2024 market, while Asia Pacific is the fastest-emerging region.

-

Plastic remains the leading material, but metal’s CAGR signals a significant growth shift ahead.

-

FDM remains a staple in printing technologies; DMLS is driving future innovation.

-

Aircraft applications top current demand; spacecraft applications present future growth potential.

-

Prototyping leads use cases now, but demand for functional parts is rising rapidly.

-

Structural components dominated end product usage; engine components are set for accelerated growth.

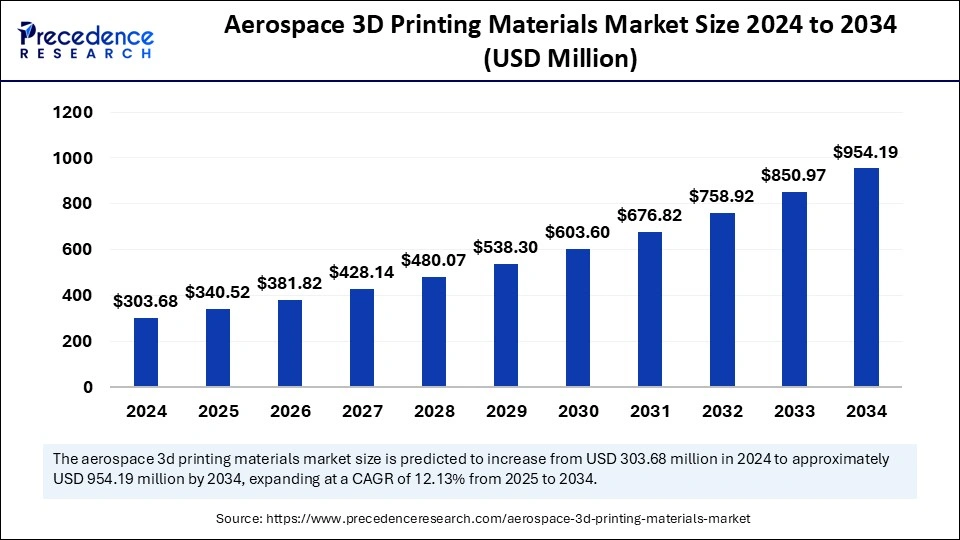

Aerospace 3D Printing Materials Market Overview

Aerospace 3D printing materials market is rapidly maturing as innovations in material science intersect with next-generation printing technologies. Materials are no longer passive substances—they are being engineered to work in tandem with specific 3D printing techniques such as Fused Deposition Modeling (FDM), Selective Laser Sintering (SLS), and Direct Metal Laser Sintering (DMLS).

The market is expanding as manufacturers demand high-performance materials optimized for speed, accuracy, and end-use durability. With aerospace shifting from prototyping to full-scale production, the spotlight is on materials that offer repeatability, mechanical precision, and reliability under extreme conditions.

Aerospace 3D Printing Materials Market Drivers

Technological advancements in additive manufacturing systems are driving new demands for compatible materials. Higher-resolution printers with multi-material capabilities necessitate powders and filaments that perform consistently across temperature variations, build volumes, and time cycles. The push toward Industry 4.0 also incentivizes the integration of data-driven production, and materials that can provide real-time feedback or adapt to variable conditions are gaining attention.

Lastly, the digital twin concept in aerospace manufacturing, where virtual replicas are matched with physical components, relies heavily on material uniformity and predictability, further boosting demand.

Aerospace 3D Printing Materials Market Opportunities

This market presents a huge opportunity in the development of hybrid materials—composites that combine the best of metals and polymers, enabling both weight reduction and structural strength. Nanomaterials and carbon-fiber-reinforced polymers are particularly promising, offering lightweight performance for both manned aircraft and unmanned aerial vehicles (UAVs).

Another opportunity lies in recyclability. As sustainability becomes a central theme in aerospace, the ability to reuse or reprocess 3D printing materials without loss of performance could become a game changer. Integration with machine learning and AI to predict material behavior and optimize usage during printing is also emerging as a growth area.

Aerospace 3D Printing Materials Market Challenges

Key technical challenges include maintaining material consistency across production batches and scaling up production without compromising quality. Powders used in metal additive manufacturing are particularly sensitive to oxidation and contamination, making storage and handling critical. Warping, delamination, and cracking are persistent issues when printing with high-temperature polymers or complex alloy systems.

Ensuring that printed parts meet fatigue, stress, and thermal resistance requirements over long operational lifetimes is another ongoing technical challenge that affects the overall reliability of the materials used.

Aerospace 3D Printing Materials Market Regional Insights

Technologically, North America and Europe lead due to the presence of advanced research labs and partnerships between academic institutions and aerospace firms. These regions are at the forefront of certifying new materials and integrating them into commercial aircraft production.

Meanwhile, countries like Japan and South Korea are investing heavily in precision materials and micro-printing techniques for aerospace microsatellites and drone applications. India and China are also emerging as strong contenders in R&D-backed growth, particularly for military aviation.

Aerospace 3D Printing Materials Market Recent Developments

Several material innovation hubs have recently been established in collaboration with aerospace companies and universities, aimed at accelerating the development of smart 3D printing materials.

Aerospace OEMs are increasingly investing in material databases to better understand performance parameters and optimize usage. Moreover, recent launches of titanium aluminide and high-temp nickel-based superalloys have opened new possibilities for jet engine component manufacturing using additive techniques.

- In July 2024, Bright Laser Technologies (BLT) introduced two new additive manufacturing materials, including a high-strength aluminum alloy specifically developed for 3D printing applications in the aerospace sector.

- In March 2025, Bambu Lab officially launched its next-generation 3D printer. The Bambu Lab H2D is an all-in-one desktop fused deposition modeling system that includes 3D printing, laser engraving, cutting, and plotting functionalities.

- In October 2023, Airbus Helicopters established a new 3D printing facility at its Donauwörth site, significantly enhancing its in-house capabilities for this innovative manufacturing process. The company operates three machines for producing titanium components, four for plastic parts, and, as a new addition, a machine that can create components made of aluminum. This process, known as additive manufacturing, can be utilized for serial production as well as for creating components for prototypes.

Aerospace 3D Printing Materials Market Top Companies

- Stratasys Ltd

- Norsk

- Materialise

- Höganäs AB

- GE

- ExOne

- EOS

- 3D Systems, Inc

Segments Covered in the Report

By Material Type

- Metal

- Plastic

- Others

By Printing Technology

- Continuous Liquid Interface Production (CLIP)

- Direct Metal Laser Sintering (DMLS)

- Fused Deposition Modeling (FDM)

- Selective Laser Sintering (SLS)

- Stereolithography (SLA)

By Platform

- Aircraft

- Spacecraft

- UAVs

By Application

- Functional Parts

- Prototyping

- Tooling

By End Product

- Structural Components

- Engine Components

- Others

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa

Ready for more? Dive into the full experience on our website!