Bonded Abrasives Market Key Takeaways

- With 55% of the market in 2024, Asia Pacific stood as the global leader.

- North America is forecasted to achieve the fastest market expansion in upcoming years.

- Europe is increasingly becoming a key region within the global market landscape.

- Grinding wheels secured the majority share of 52% in the product type segment in 2024.

- The polishing wheels category is likely to experience robust growth over the forecast term.

- The automotive industry captured the largest share by end-use, contributing 41% in 2024.

- The aerospace segment is anticipated to grow prominently in the near future.

Market Overview

The bonded abrasives market is integral to a wide range of industries requiring material removal and finishing processes. From automotive and aerospace to general engineering and electronics, bonded abrasives support vital applications that demand accuracy, consistency, and efficiency. These abrasives consist of abrasive grains bound together using resin, vitrified, or rubber-based bonding agents, forming solid tools like wheels and segments used in grinding, polishing, and cutting.

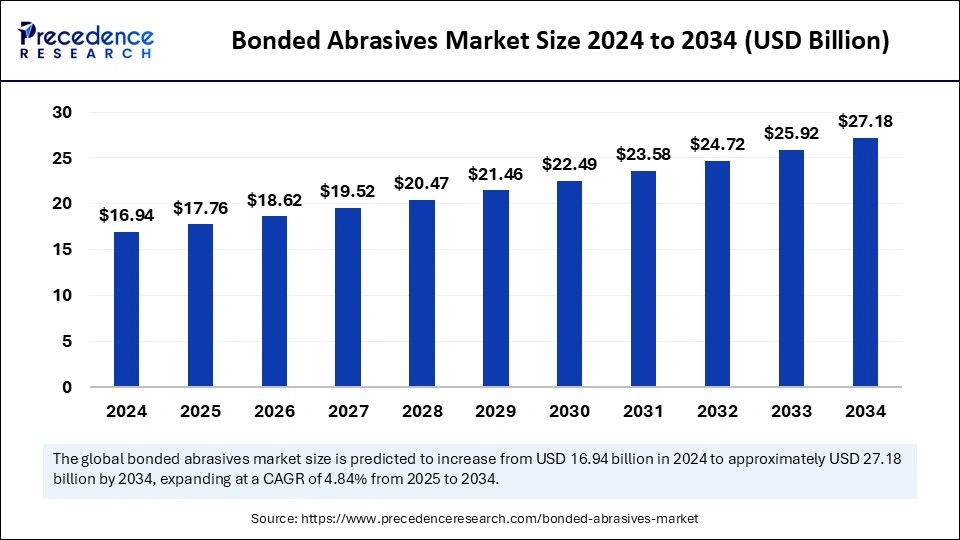

The bonded abrasives market continues to grow due to increased industrial activity and the expansion of manufacturing capabilities worldwide. In 2024, the market stands at a robust valuation and is expected to maintain strong momentum through 2034. Factors such as increased automation, demand for lightweight materials, and the need for high-performance finishing tools are driving this growth. The increasing reliance on bonded abrasives in high-speed machining and robotics further highlights their role in modern production environments.

Drivers

Several factors drive the bonded abrasives market. Among the most influential is the global expansion of automotive manufacturing. Grinding and finishing operations are essential in automotive production, from engine blocks to suspension parts. As the automotive sector grows, especially in Asia and Europe, the demand for bonded abrasives continues to surge.

The aerospace industry is another major contributor to bonded abrasives market growth. The need for precision grinding in the production of turbine blades, fuselage sections, and gear components necessitates high-quality bonded abrasives capable of maintaining performance under extreme conditions. With growing aircraft backlogs and the rise of commercial aviation, abrasive tools are increasingly in demand.

Urbanization and construction booms, particularly in developing nations, are also propelling the bonded abrasives market. These abrasives are widely used for shaping, smoothing, and cutting construction materials, providing versatility and strength for on-site and off-site applications.

Opportunities

Opportunities in the bonded abrasives market abound, particularly with the emergence of electric mobility and renewable energy. EV manufacturing presents a need for abrasives that can handle advanced materials and tight component tolerances. Bonded abrasives suitable for grinding aluminum alloys, composites, and battery components are seeing growing interest.

In renewable energy, especially wind and solar energy, there is a need for bonded abrasives in the fabrication of turbines, frames, and structural components. The bonded abrasives market is poised to benefit from the global shift toward sustainable energy sources.

Digitization of industrial processes offers further potential. The incorporation of smart abrasives that integrate IoT capabilities enables real-time data collection, process optimization, and predictive maintenance. This is particularly beneficial in high-precision industries and could redefine how bonded abrasives are used in next-gen manufacturing systems.

Challenges

The bonded abrasives market faces its fair share of challenges. Raw material availability remains a critical concern. Disruptions in the supply of grains such as silicon carbide or aluminum oxide can impact production and delay delivery schedules. Rising transportation costs and geopolitical uncertainties further exacerbate the issue.

Additionally, the bonded abrasives market faces stiff competition from alternative abrasive technologies like coated abrasives and superabrasives. While bonded abrasives remain cost-effective, they must evolve to keep pace with higher precision and longer-lasting solutions.

Workplace safety and environmental regulations also impose operational constraints. Manufacturers must meet stringent safety standards and manage emissions and waste associated with bonded abrasives. This requires continuous investment in cleaner technologies and safer product designs.

Regional Insights

The Asia Pacific region dominates the bonded abrasives market with over half of global demand originating from this area in 2024. Its dominance is attributed to high-volume manufacturing in countries such as China and India. Growth in infrastructure development, coupled with expanding automotive and electronics sectors, ensures continued demand for bonded abrasives.

North America maintains a strong position in the bonded abrasives market due to advanced technological adoption and an emphasis on high-value industries such as aerospace and precision machining. The region’s focus on smart manufacturing and innovation supports demand for high-performance abrasives.

Europe’s bonded abrasives market reflects steady growth supported by a mature manufacturing sector and the adoption of green technologies. Countries like Germany and France are leading the push for sustainable abrasive solutions and stringent quality standards.

The Middle East, Africa, and Latin America are becoming increasingly important as manufacturing bases shift and infrastructure investments grow. These regions represent the next frontier for expansion within the bonded abrasives market.

Recent Developments

Recent innovations have significantly enhanced the capabilities of the bonded abrasives market. Key players are launching new products with enhanced grain composition, offering better heat resistance and prolonged operational life. These improvements help industries meet tighter production schedules while maintaining product quality.

Digital integration is a rising trend in the bonded abrasives market. Smart sensors embedded in abrasive tools allow users to monitor wear and optimize grinding parameters in real time. This approach leads to more efficient operations and helps prevent unexpected tool failures.

Strategic alliances and geographic expansion have also been on the rise. Companies are opening new production facilities closer to demand centers, reducing lead times and improving customer service. Collaborations with automotive and aerospace manufacturers are helping abrasive producers align their R&D with evolving customer requirements.

Bonded Abrasives Market Companies

- Nippon Resibon Corporation

- Carborundum Universal Limited

- Buffalo Abrasives

- Abrasives Manhattan

- Marrose Abrasives

- Grinding Techniques Ltd

- SAK Abrasives Limited

- Sia Abrasives Industries AG

- Flexovit

- Saint-Gobain

Segments Covered in the Market

By product type

- Grinding wheels

- Cutting wheels

- Polishing wheels

- Other product types

By end use

- Automotive

- Aerospace

- Metalworking

- Other end uses

By region

- North America

- Asia Pacific

- Europe

- Latin America

- Middle East and Africa

Ready for more? Dive into the full experience on our website!