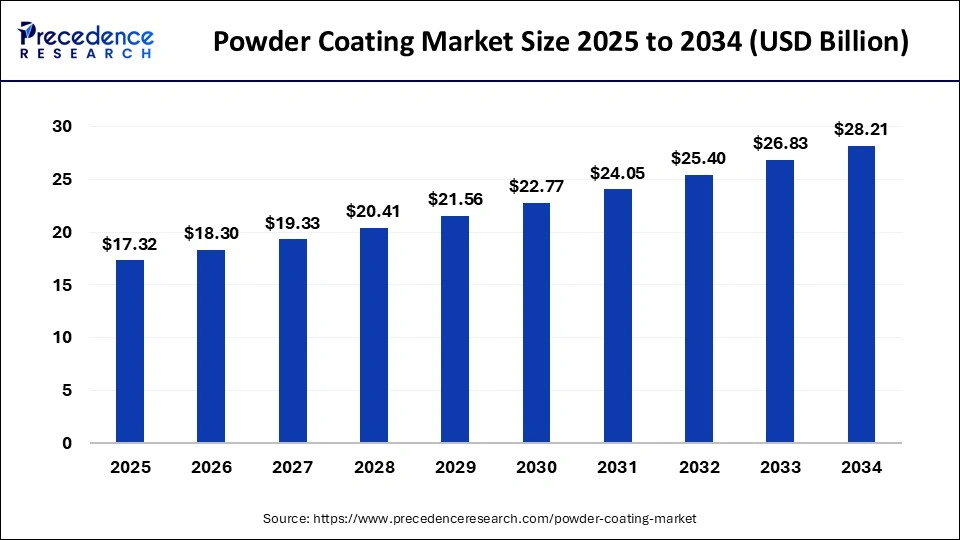

The global powder coating market is expected to grow from USD 16.40 billion in 2024 to USD 28.21 billion by 2034, with a CAGR of 5.57%.

Powder Coating Market Key Takeaways

- Asia Pacific dominated the market with a revenue share of over 40% in 2024.

- By region, the market in North America is expected to grow at the fastest rate over the projection period.

- By application, the consumer goods segment dominated the market in 2024.

- By resin, the polyester segment held the largest share of the market in 2024.

- By resin, the epoxy-polyester segment is anticipated to expand rapidly during the forecast period.

Market Overview

The powder coating market has witnessed remarkable growth over the past decade, driven by its widespread adoption across diverse industries such as automotive, construction, appliances, and furniture. Powder coating offers a superior and environmentally friendly alternative to traditional liquid coatings, providing excellent durability, corrosion resistance, and aesthetic appeal. The increasing focus on sustainability and the need for high-performance coatings have propelled the demand for powder coatings in various applications.

With stringent environmental regulations limiting the use of solvent-based coatings, industries are shifting toward powder coating solutions that minimize VOC emissions. Additionally, the ability of powder coatings to deliver a thicker and more uniform finish with minimal waste contributes to their growing popularity. The development of advanced powder coating formulations, such as UV-cured and heat-sensitive coatings, has further expanded the scope of applications, enabling growth across multiple industries.

Drivers

-

Stringent Environmental Regulations on VOC Emissions

Regulatory bodies across the globe are enforcing strict limits on VOC emissions, prompting industries to adopt powder coatings as a sustainable alternative. Powder coatings generate little to no harmful emissions, aligning with the global push toward environmentally responsible manufacturing practices. -

Increased Demand for Durable and Aesthetic Finishes

Industries such as automotive, furniture, and consumer goods demand durable and aesthetically pleasing finishes that enhance product quality. Powder coatings provide a uniform and durable finish that resists chipping, corrosion, and fading, making them an ideal choice for applications requiring long-lasting protection. -

Surge in Infrastructure and Construction Projects

Rapid urbanization and infrastructure development in emerging economies have increased the demand for powder coatings in construction applications. Architectural elements such as aluminum profiles, metal doors, and window frames benefit from the superior protection offered by powder coatings. -

Rising Adoption of Powder Coatings in the Appliance Industry

The appliance industry is a major consumer of powder coatings, utilizing them for coating refrigerators, washing machines, ovens, and other household appliances. Powder coatings enhance the durability and visual appeal of appliances, contributing to their long lifespan.

Opportunities

-

Growing Demand for UV-Cured and Heat-Sensitive Coatings

The development of UV-cured and heat-sensitive powder coatings has created new opportunities in industries that require faster curing times and reduced energy consumption. These coatings provide enhanced performance while minimizing the environmental impact of the curing process. -

Expansion of the Automotive Refinish Market

The increasing demand for automotive refinish coatings, driven by rising vehicle ownership and the need for high-quality finishes, presents growth opportunities for the powder coating market. Powder coatings are increasingly used in the refinish sector due to their superior durability and resistance to environmental factors. -

Increasing Use of Powder Coatings in 3D Printing Applications

The growing popularity of 3D printing technologies in manufacturing industries has created opportunities for the use of powder coatings to enhance the surface finish and durability of 3D-printed components.

Challenges

-

Technical Limitations in Coating Complex Geometries

Achieving uniform coverage on complex geometries and intricate parts can be challenging with powder coatings. This limitation restricts the applicability of powder coatings in certain industries where precision coating is required. -

High Energy Consumption During Curing Process

The curing process for powder coatings typically requires high temperatures, leading to increased energy consumption. This can pose a challenge for industries seeking to minimize their carbon footprint and operational costs. -

Intense Competition from Liquid Coatings and Emerging Alternatives

The powder coating market faces competition from liquid coatings and other emerging coating technologies that offer comparable performance and application flexibility. This competitive landscape puts pressure on powder coating manufacturers to innovate and differentiate their offerings.

Regional Insights

-

Asia Pacific

Asia Pacific remains the dominant region in the powder coating market, accounting for a significant share of global revenue. The region’s strong manufacturing base, coupled with growing demand for consumer goods and automotive products, has fueled market growth. -

North America

North America is expected to witness the highest growth rate due to the increasing adoption of eco-friendly coating solutions and the rising demand for high-performance coatings in industrial and automotive applications. -

Europe

Europe’s focus on reducing carbon emissions and enhancing energy efficiency has driven the adoption of powder coatings in construction, automotive, and industrial applications. -

Middle East and Africa

The Middle East and Africa region is experiencing steady growth in the powder coating market due to infrastructure development and government initiatives to promote industrialization.

Recent News

-

Launch of Innovative Low-Temperature Powder Coatings

Key manufacturers have introduced low-temperature curing powder coatings that reduce energy consumption while maintaining superior performance and durability. -

Expansion of Manufacturing Facilities to Strengthen Market Presence

Leading companies are investing in expanding their manufacturing facilities to cater to the rising demand for powder coatings globally, enhancing production capacity and improving supply chain efficiency.

Powder Coating Market Companies

- Axalta Coating Systems

- The Sherwin-Williams Company

- Arkema Group

- The Valspar Corporation

- Eastman Chemical Company

- PPG Industries, Inc.

- Akzo Nobel NV

- Evonik Industries AG

- Nippon Paint Co., Ltd.

Segments Covered in the Report

By Resin

- Epoxy-Polyester

- Epoxy

- Acrylic

- Polyester

- Polyurethane

- Others

By Application

- Automotive

- Consumer Goods

- Architectural

- Furniture

- Oil and Gas

- Pipeline

- Others

By Geography

- North America

- Europe

- Asia-Pacific

- Latin America

- Middle East & Africa