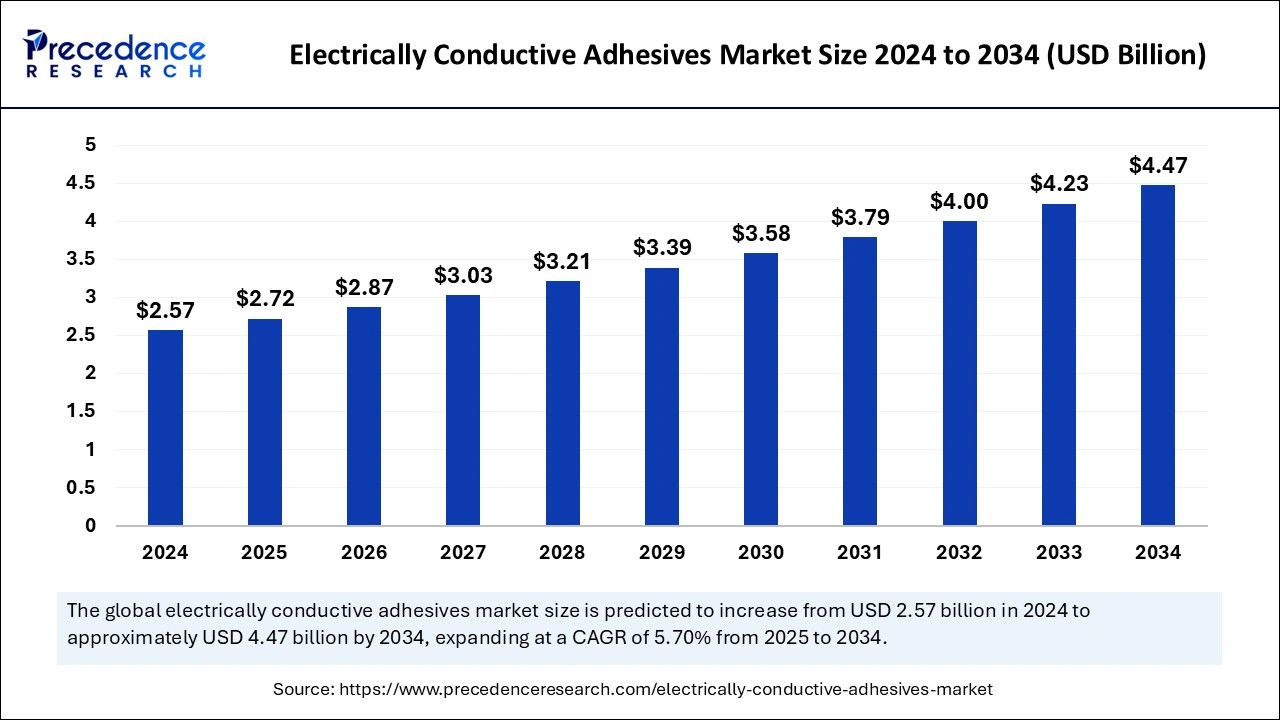

Electrically conductive adhesives market size to expand from USD 2.57 billion in 2024 to USD 4.47 billion by 2034, growing at a CAGR of 5.70%.

Electrically Conductive Adhesives Market Key Takeaways

-

The electrically conductive adhesives market was led by Asia Pacific, securing the highest market share of 34% in 2024.

-

North America is predicted to witness substantial growth during the forecast period.

-

By type, isotropic conductive adhesives held a significant share of the market in 2024.

-

The anisotropic conductive adhesives segment is estimated to grow at the fastest pace throughout the forecast period.

-

The epoxy segment led the market by chemistry, contributing 34% of the total market share in 2024.

-

The silicone segment is expected to register the most rapid growth during the forecast period.

-

The silver filler segment accounted for a noteworthy portion of the market in 2024.

-

By application, the automotive segment recorded the highest market share in 2024.

Electrically Conductive Adhesives Market Overview

The electrically conductive adhesives market is undergoing rapid transformation as industries shift toward advanced bonding solutions for electronic components. These adhesives serve as an efficient alternative to soldering, offering benefits such as lightweight construction, enhanced durability, and improved compatibility with sensitive materials. Their applications span consumer electronics, automotive, aerospace, medical devices, and renewable energy, making them an essential component in next-generation electronic assembly.

Conductive adhesives consist of two major components, one of which is an adhesive base matrix and the other a conductive metal filler. Electronic and electrical component joining requires electrically conductive adhesives. The adhesives serve circuit assembly requirements, which require heat curing and hot soldering methods.

The filling components of this material include silver, copper, graphite, and nickel. The mixture includes fillers that enable easy electrical conduction while ensuring outstanding adhesive capabilities and the required physical quantities.

Epoxy and silicon-based electrically conductive adhesives are used throughout the construction, aerospace, and electronics sectors. The electrically conductive adhesives market has demonstrated a notable expansion in recent years while anticipating continued growth during future periods. This growth can be attributed to manufacturers constantly seeking to produce miniaturized electronic devices like smartphones with lightweight equipment, including tablets and wearable devices.

The market value further expands due to two major developments: the rising popularity of electric-powered vehicles and the rising need for renewable power generation equipment

Electrically Conductive Adhesives Market Drivers

The growing demand for high-reliability electronics in aerospace and military applications is a key driver for the market. The automotive sector is also fueling demand as manufacturers incorporate more electronic components into electric vehicles and autonomous systems. The rise of smart manufacturing and automation is increasing the need for precision adhesives that ensure efficient electronic connections. Furthermore, innovations in nanotechnology are improving the performance and conductivity of adhesives, making them more viable for high-end applications.

Electrically Conductive Adhesives Market Opportunities

The expansion of 3D printing and additive manufacturing in electronics presents a new avenue for conductive adhesive applications. The increasing demand for transparent and stretchable conductive adhesives in flexible electronics is also opening up novel opportunities. Government initiatives promoting sustainable manufacturing and green electronics are expected to boost the market further. Additionally, advancements in self-healing adhesives that can repair micro-cracks in circuits could revolutionize the industry.

Electrically Conductive Adhesives Market Challenges

The industry faces challenges related to cost, as conductive adhesives remain more expensive than conventional materials. Ensuring long-term conductivity stability and adhesion strength in extreme conditions is another hurdle. Moreover, the development of standardized testing and quality control measures remains a priority for industry stakeholders.

Electrically Conductive Adhesives Market Regional Insights

Asia-Pacific continues to dominate the market, with leading electronics manufacturers driving demand. North America and Europe are focusing on high-performance applications, particularly in aerospace and medical electronics. Latin America and the Middle East are emerging markets with growing investments in advanced materials.

Electrically Conductive Adhesives Market Recent Developments

Breakthroughs in graphene-based conductive adhesives are improving performance and sustainability. Major players are launching new formulations with enhanced conductivity and lower environmental impact. Partnerships between tech companies and adhesive manufacturers are accelerating product development for next-generation electronic devices.

- In September 2024, German adhesive supplier Panacol released Elecolit 3648, which represents a one-component electrically conductive adhesive (ECA) designed to connect flexible perovskite and organic PV modules. This product was developed to create excellent attachment to multiple plastic materials.

- In June 2023, Polytec PT joined forces with Bostik and launched a fresh thermal conductive adhesives (TCAs) product family for thermal management of e-mobility applications in cell-to-pack battery designs.

In May 2023, Henkel unveiled Loctite TLB 9300 APSi as an innovative injectable thermally conductive adhesive to supply structural bonding together with thermal conductivity abilities for EV battery system solutions.

Electrically Conductive Adhesives Market Companies

- Henkel AG & Co. KGaA

- Dow Corning Corporation

- 3M Company

- Aremco Products, Inc.

- Parker Hannifin Corporation

- Panacol-Elosol GmbH

- Masterbond Inc.

- H.B. Fuller Company

- MG Chemicals Ltd.

- Creative Materials Inc.

- Permabond Engineering Adhesives Ltd.

- Polytec PT GmbH

Segments Covered in the Report

By Type

- Isotropic Conductive Adhesives

- Anisotropic Conductive Adhesives

By Chemistry

- Epoxy

- Polyurethane

- Silicone

- Acrylic

- Others

By Filler Material

- Silver Fillers

- Copper Fillers

- Carbon Fillers

- Others

By Application

- Automotive

- Biosciences

- Consumer Electronics

- Aerospace

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa