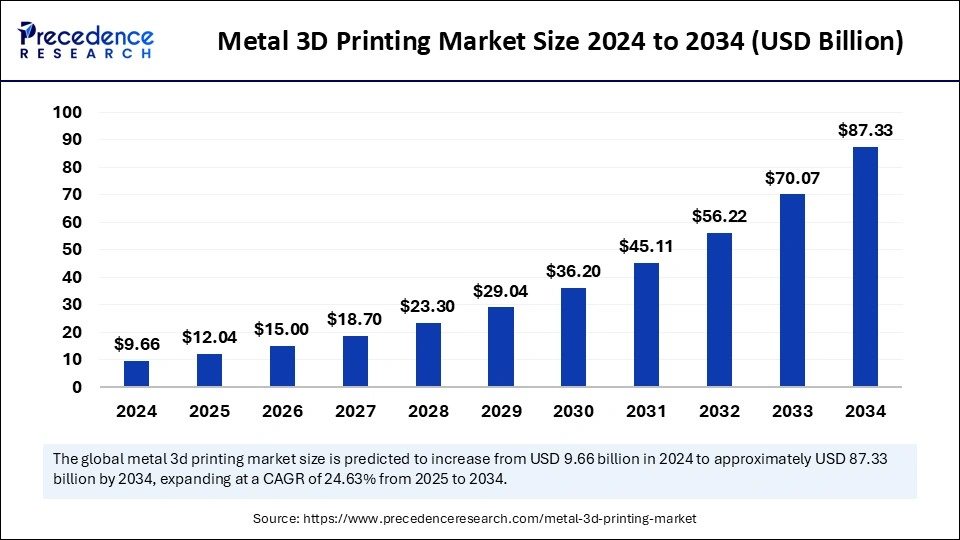

Metal 3D printing market size stood at USD 9.66 billion in 2024 and is forecast to surge to USD 87.33 billion by 2034, registering a CAGR of 24.63%.

-

In 2024, North America accounted for the largest market share at 34%.

-

Asia Pacific is set to grow at the highest CAGR during the forecast years.

-

Europe is forecast to register considerable growth throughout the projected period.

-

Among technologies, Selective Laser Melting (SLM) led the market in 2024.

-

Electron Beam Melting (EBM) is projected to expand significantly between 2025 and 2034.

-

Design software dominated the software segment in 2024 by capturing the largest share.

-

The scanners software category is expected to grow at an impressive CAGR during the forecast years.

-

In terms of components, hardware held a 65% market share in 2024.

-

The services component is anticipated to show the fastest growth in the coming years.

-

The prototyping segment held the highest market share by application in 2024.

-

Functional parts are expected to grow rapidly in the application segment over the forecast span.

-

The industrial printer segment led the market by type in 2024.

-

Desktop printers are likely to grow at a strong CAGR through the forecast period.

Metal 3D Printing Market Overview

Metal 3D printing, also known as metal additive manufacturing, has transitioned from a niche technology into a transformative force across industries.

The market is being redefined by innovations in hardware, software, and materials, enabling manufacturers to rethink product design and functionality. From intricate aerospace components to custom medical implants, metal 3D printing is enabling faster development cycles, cost savings, and unprecedented design freedom.

Metal 3D Printing Market Drivers

The increasing demand for performance-driven, weight-reducing components across aerospace, defense, and medical sectors is driving the Metal 3D Printing Market.

Additionally, the shift toward digital manufacturing and supply chain resilience has made localized, on-demand production more attractive. The evolution of sintering techniques, directed energy deposition, and binder jetting has also expanded the market’s application scope.

Metal 3D Printing Market Opportunities

A growing trend in the Metal 3D Printing Market is the rise of decentralized production, allowing companies to manufacture critical parts on-site and on-demand. This is especially promising in remote or mission-critical environments like space or military operations. There is also growing potential in tooling and mold-making, where metal 3D printing significantly reduces lead time and increases tool life.

The exploration of green manufacturing through recyclable and sustainable metal powders presents another key opportunity.

Metal 3D Printing Market Challenges

Key challenges facing the Metal 3D Printing Market include the high cost of machines and feedstock materials, as well as the need for advanced design expertise. The lack of a skilled workforce and limited understanding of additive design principles among traditional manufacturers remains a bottleneck.

Additionally, quality assurance and repeatability continue to be significant hurdles, particularly in high-regulation industries.

Metal 3D Printing Market Regional Insights

North America continues to be a technology hub for the Metal 3D Printing Market, with substantial R&D investments and early adoption by key sectors. Europe benefits from strong academic-industry collaborations, particularly in Germany and France.

Asia-Pacific is emerging as a dynamic market, with China expanding its additive manufacturing capabilities and India positioning itself as a potential hub for low-cost innovation. Regions like the Middle East are focusing on using metal 3D printing for infrastructure and energy applications.

Metal 3D Printing Market Recent Developments

Recent advancements include the introduction of high-speed laser powder bed fusion systems and hybrid manufacturing platforms combining additive and subtractive processes. Startups and tech giants alike are investing in metal 3D printing services and cloud-based platforms, fostering ecosystem growth.

Certification programs for metal 3D printed parts are gaining traction, particularly in aerospace and medical sectors, signaling a shift toward mainstream adoption.

Metal 3D Printing Market Companies

- Cognex Corporation

- Basler AG.

- Sick AG

- 3D Systems Corporation (U.S.)

- Stratasys Ltd.

- Renishaw plc

- General Electric Company

- Carpenter Technology Corporation

- Materialise NV

- Voxeljet AG

- Sandvik AB

- EOS GmbH Electro Optical Systems

Segment Covered in the Report

By Technology

- Selective Laser Sintering

- Direct Metal Laser Sintering

- Inkjet printing

- Electron Beam Melting

- Laser Metal Deposition

- Laminated Object Manufacturing

- Electron Beam Freeform Fabrication

- Selective Laser Melting

By Software

- Design Software

- Inspection Software

- Printer Software

- Scanning Software

By Component

- Hardware

- Software

- Services

By Application

- Prototyping

- Tooling

- Functional Parts

By Printer Type

- Desktop Metal 3D Printer

- Industrial Metal 3D Printer

By Region

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East & Africa

Ready for more? Dive into the full experience on our website!