X-Ray Inspection System Market Key Takeaways

X-Ray Inspection System Market Key Takeaways- North America dominated the global market with the largest market share of 37% 2024.

- Asia Pacific is estimated to expand the fastest CAGR in the market between 2025 and 2034.

- Europe has been witnessing notable growth in the global market.

- By technology, the digital imaging segment held the largest market share in 2024.

- By technology, the film-based imaging segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

- By dimension, the 2D X-ray segment contribute the biggest market share in 2024.

- By dimension, the 3D X-ray segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

- By end-user, the manufacturing segment captured the highest market share in 2024.

- By end-user, the aerospace segment is anticipated to grow at a remarkable CAGR between 2025 and 2034.

Market Overview

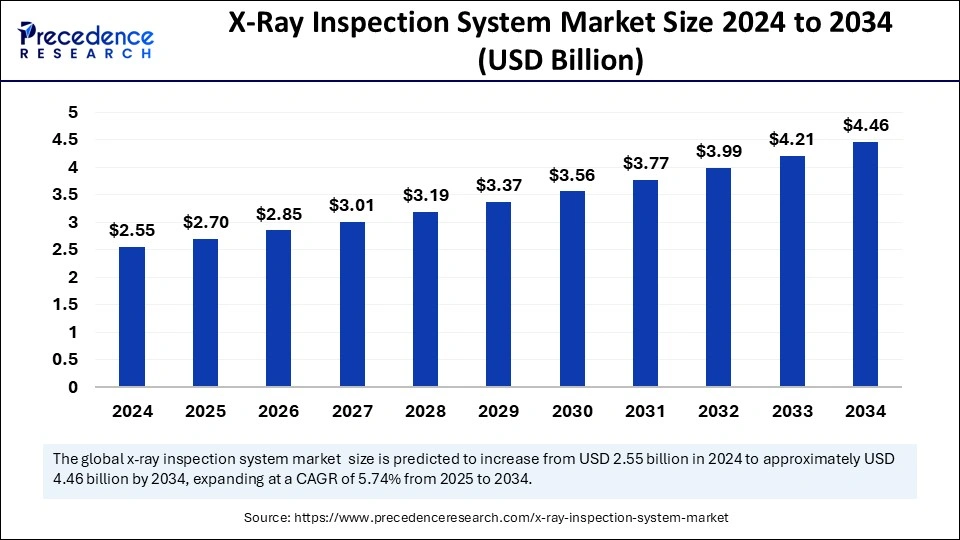

The X-ray inspection system market is experiencing significant transformation as industries worldwide turn to advanced non-destructive testing methods for quality control and safety assurance. These systems are integral to detecting internal flaws, contaminants, and structural inconsistencies in products across sectors such as electronics, food processing, automotive, and aerospace. The market is being shaped by increasing automation in manufacturing and tighter global regulations that demand precision and accountability in product inspections. As such, the X-ray inspection system market is poised for robust expansion in the coming years.

Drivers

The primary driver of the X-ray inspection system market is the need for superior quality assurance mechanisms that can operate under demanding industrial conditions. Governments and regulatory bodies around the world are enforcing stricter quality and safety regulations, especially in sectors like food and pharmaceuticals. The miniaturization of electronic components also necessitates high-resolution inspection technologies to identify microscopic defects. As smart manufacturing and Industry 4.0 technologies become more widespread, the integration of X-ray systems into automated production lines is further boosting market adoption.

Opportunities

The future of the X-ray inspection system market lies in digital transformation and software-driven innovation. Opportunities abound in cloud-based data analysis, automated defect detection algorithms, and integration with manufacturing execution systems (MES). The expansion of electric vehicles and battery production facilities is opening new avenues for inspection applications in energy storage and powertrain components. Markets in Southeast Asia and Africa offer untapped potential, where growing industrialization is driving the demand for reliable quality control infrastructure. Additionally, tailored solutions for small and mid-sized businesses can open new revenue streams for manufacturers.

Challenges

The X-ray inspection system market does face constraints, notably the high capital investment required for equipment acquisition and staff training. Regulatory compliance and safety measures for radiation use pose barriers to entry in certain industries. Another challenge is maintaining system sensitivity and accuracy in high-throughput production environments. Technical limitations in inspecting complex materials or geometries can also hinder system effectiveness. Furthermore, the lack of standardized inspection protocols across regions can affect market uniformity and slow down international expansion.

Regional Insights

North America leads the X-ray inspection system market, supported by technological leadership and early adoption across diverse industries. Europe’s stringent quality standards and robust pharmaceutical and automotive sectors also contribute significantly to the market’s growth. The Asia-Pacific region is emerging as a major market, with China and India ramping up investments in advanced manufacturing and food safety. Japan and South Korea are pioneering innovations in electronics inspection, while Australia is gradually expanding its use of X-ray systems in mining and agriculture. The Middle East and Latin America are also increasing adoption in logistics and border control.

Recent Developments

Recent progress in the X-ray inspection system market includes the deployment of dual-energy systems for more accurate material discrimination. Advanced software tools are now enabling 3D image reconstruction and predictive analytics, helping manufacturers prevent defects before they occur. Industry leaders are forming strategic alliances to enhance product offerings and expand global reach. Companies are also focusing on developing eco-friendly, lower-radiation systems to meet environmental and safety concerns. Mobile and inline X-ray units are becoming more prevalent, providing flexibility and speed in fast-paced manufacturing settings.

X-Ray Inspection System Market Companies

- North Star Imaging Inc.

- Nikon Metrology, Inc.

- Nordson Corporation

- YXLON International GmbH

- VJ Group, Inc.

- Mettler Toledo International Inc.

- Ametek, Inc.

- Viscom AG

- ViTrox Corporation Berhad

- Test Research, Inc.

Segments Covered in the Report

By Technology

- Digital Imaging

- Film-based imaging

By Dimension

- 2D

- 3D

By End Use

- Manufacturing

- Oil and Gas

- Aerospace

- Automotive

- Others

By Geography

- North America

- Europe

- Asia Pacific

- Latin America

- Middle East and Africa